6061合金中的主要合金元素为镁及硅,具有中等强度,良好的抗腐蚀性,可焊接性,氧化效果好. 属Al-Mg-Si系合金,中等强度,具有良好的塑性和优良的耐蚀性。特别是无应力腐蚀开裂倾向,其焊接性优良,耐蚀性及冷加工性好,是一种使用范围广.很有前途的合金。可阳极氧化着色,也可涂漆上珐琅,适应作建筑装饰材料。其含有少量Cu,因而强度高于6063的,但淬火敏感性也比6063高,挤压之后不能实现风淬,需要重新固溶处理和淬火时效,才能获得较高的强度。

要求有一定强度、可焊接性与抗腐蚀性高的各种工业结构件,如制造:卡车、搭式建筑、船舶、电车、家具、机械零件、精密加工,工业用料比较广泛等。

| 化学元素 | |||||||||||||||||||||||||

| 元素 | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | V | Zr | 其它 | Al | ||||||||||||

| 单个 | 合计 | ||||||||||||||||||||||||

| 含量 | 0.40~0.8 | 0.70 | 0.15~0.40 | 0.15 | 0.8~1.2 | 0.04~0.35 | - | 0.25 | 0.15 | - | - | 0.05 | 0.15 | 余量 | |||||||||||

| 机械性能 | ||||||||||||

| 合金状态 | AMS-QQ-A-250/11 | AMS 4027 | ||||||||||

| 厚度/inch | 抗拉强度/KSI | 屈服强度/KSI | 断后延伸率/% | 厚度/mm | 抗拉强度/Mpa | 屈服强度/Mpa | 断后延伸率/% | |||||

| A50mm | A | A50mm | A | |||||||||

| 6061-T6 | 0.006<T≤0.007 | ≤42.0 | ≤35.0 | 4% | - | 0.15<T≤0.18 | ≥290 | ≥241 | 4 | - | ||

| 0.007<T≤0.009 | ≤42.0 | ≤35.0 | 6% | - | 0.18<T≤0.23 | ≥290 | ≥241 | 6 | - | |||

| 0.009<T≤0.020 | ≤42.0 | ≤35.0 | 8% | - | 0.23<T≤0.51 | ≥290 | ≥241 | 8 | - | |||

| 0.020<T≤0.249 | ≤42.0 | ≤35.0 | 10% | - | 0.51<T≤12.67 | ≥290 | ≥241 | 10 | - | |||

| - | - | - | - | - | 12.67<T≤25.4 | ≥290 | ≥241 | 9 | - | |||

| - | - | - | - | - | 25.4<T≤50.8 | ≥290 | ≥241 | 8 | - | |||

| - | - | - | - | - | 50.8<T≤101.6 | ≥290 | ≥241 | 6 | - | |||

| - | - | - | - | - | 101.6<T≤152.4 | ≥276 | ≥241 | 6 | - | |||

| - | - | - | - | - | - | - | ||||||

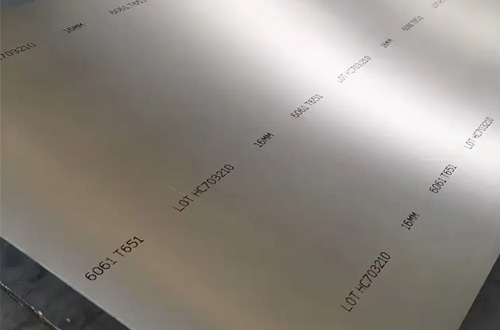

| 6061-T651 | 0.250<T≤0.499 | ≤42.0 | ≤35.0 | 10% | - | 0.15<T≤0.18 | ≥290 | ≥241 | 4 | - | ||

| 0.500<T≤1.000 | ≤42.0 | ≤35.0 | 9% | - | 0.18<T≤0.23 | ≥290 | ≥241 | 6 | - | |||

| 1.000<T≤2.000 | ≤42.0 | ≤35.0 | 8% | - | 0.23<T≤0.51 | ≥290 | ≥241 | 8 | - | |||

| 2.000<T≤3.000 | ≤42.0 | ≤35.0 | 6% | - | 0.51<T≤12.67 | ≥290 | ≥241 | 10 | - | |||

| 3.000<T≤4.000 | ≤42.0 | ≤35.0 | 6% | - | 12.67<T≤25.4 | ≥290 | ≥241 | 9 | - | |||

| 4.000<T≤6.000 | ≤40.0 | ≤35.0 | 6% | - | 25.4<T≤50.8 | ≥290 | ≥241 | 8 | - | |||

| - | - | - | - | - | 50.8<T≤101.6 | ≥290 | ≥241 | 6 | - | |||

| - | - | - | - | - | 101.6<T≤152.4 | ≥276 | ≥241 | 6 | - | |||

| - | - | - | - | - | - | - | - | - | - | |||